- Home

- Internal devices of columns and apparatuses

- Plastic tower packingPlastic Packing NetBallLamella clarifiers tube settler plate separatorPlastic packing Q-packPlastic Pall ringsHeat-insulating balls for Sous Vide Plastic packing Tri PackSpiral packing Tellerette RingPlastic conjugate rings Filter Media MBBRPlastic Heilex ringsHollow floatation ballsABS filter nozzlePTFE Pall ringsPlastic hollow balls Polypropylene media Biopack 180 mm Bacterial FilterElastic solid packingPlastic Nu-Pack packingPlastic Lan Pack packingCooling tower infillsPlastic Structured PackingLiquid Surface Covering BallPolyhedral Hollow BallsPlastic Raschig ringsFloating Bio ballsPTFE Raschig ringsHDPE shade ballsInner Arc (VSP) RingsSnow Flower RingsPlastic Cascade Rings

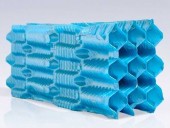

- Cooling tower infills

Cooling tower infills

Cooling tower film, cooling tower film filler, plastic sheet for cooling tower filler.

Cooling Tower Fill Characteristics

- Acid resistance.

- Alkali resistance.

- Corrosion protection for organic solvent.

- Good ignition retardation performance.

- Increase in cross-sectional area.

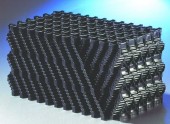

An introduction to film fillers in cooling towers.

Cross grooved film fillers improve Water Distribution by separating the water flow as it passes through the filler. The CF1900 MA separates water flow 8 times along a 12" (305 mm) vertical path. High thermal performance (high CAB/L) and low pressure drop are simultaneously achieved through clever groove/microstructure design and the highest manufacturing standards. The PVC film is filled with 19 mm spacing. The larger sheet spacing is suitable for water quality that is slightly different from ideal.

CF1900MA is used in counterflow cooling towers and is available in bonded blocks 305 mm wide and 305 mm high and in lengths of 1830 mm or 2440 mm. CF1900MA can also be cut to length to suit your specific requirements or supplied as individual sheets.

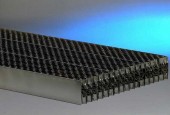

Features of the film fill of a cooling tower.

- The bevelled tips promote drainage at the joints of the filler bags.

- Comes with patented Mechanical Assembly (MA) technology for glueless packs that can be assembled on site.

- A microstructure is designed to improve water distribution and thermal mixing.

- High thermal performance.

- A proprietary edge treatment that directs water to both sides of the sheet.

- The material complies with the Refrigeration Technology Institute (CTI) standard 136.

- Available in PVC and CPVC.

Application of film fill media for cooling tower.

CF1900 is designed for field erected or packaged counterflow cooling towers and can be used in crossflow cooling towers. This fill is used in the power generation, petroleum refining, chemical, metallurgical and food processing industries where water quality is average to good.

Application of cooling tower filler PVC / plastic sheet for cooling tower filling. It is widely used in various types of large, medium, small cooling towers.

| Producer | BTS Engineering |

| Material | PVC, PP |

| Operating temperature | -35-85 |

| Dimensions, mm | 1000x500 |

| Thickness mm | 0.35-0.6 |

| Producer | BTS Engineering |

| Material | PVC, PP |

| Operating temperature | -35-85 |

| Dimensions, mm | 1220*305*305 |

| Thickness mm | 0.35-0.6 |

| Producer | BTS Engineering |

| Material | PVC, PP |

| Operating temperature | -35-65 |

| Dimensions, mm | 1000x500 |

| Thickness mm | 0.3-0.5 |

| Producer | BTS Engineering |

| Material | PVC, PP |

| Operating temperature | -35-65 |

| Dimensions, mm | 1000x500 |

| Thickness mm | 0.3-0.5 |

| Producer | BTS Engineering |

| Material | PVC, PP |

| Operating temperature | -35-60 |

| Dimensions, mm | 1000x500 |

| Thickness mm | 0.25-0.3 |

| Producer | BTS Engineering |

| Material | PVC, PP |

| Operating temperature | -35-100 |

| Dimensions, mm | 1000x500 |

| Thickness mm | 0.35-0.5 |

| Producer | BTS Engineering |

| Material | PVC |

| Operating temperature | -35-75 |

| Thickness mm | 0.33-0.35 |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PVC |

| Operating temperature | -20-68 |

| Thickness mm | 0.28-0.45 |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PP |

| Dimensions, mm | 2400 x 300 x 300 mm |

| Nozzle type | Fillers |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PP |

| Dimensions, mm | 2400 x 300 x 300 mm |

| Nozzle type | Fillers |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PP |

| Dimensions, mm | 2400 x 300 x 300 mm |

| Nozzle type | Fillers |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PP |

| Dimensions, mm | 2400 x 610 x 130 mm |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PP |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PVC |

| Dimensions, mm | 1800х600 |

| Nozzle type | Fillers |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PVC |

| Dimensions, mm | 600x600 |

| Nozzle type | Fillers |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |

| Producer | BTS Engineering |

| Material | PVC |

| Dimensions, mm | 300х600 |

| Nozzle type | Fillers |

| Analogue for | Pall Ring Company, Koch-Glitsch, НКС DOLSIN, AMACS, Ultimo Engineers, MTE, MACH Engineering LLC, Munters, Christy Catalytics |