- Home

- Shut-off valves

Shut-off valves

Pipe fittings are a whole range of products used in industry and everyday life. These products are installed on:

- Factory pipes. Industrial devices can be of any diameter.

- Plumbing pipelines. The main types of fittings on pipelines include faucets, ball valves, valves and pressure regulators.

- Experimental installations. This equipment is not mass-produced. It is made to order.

Types of shut-off valves

Depending on the scope of application, shut-off and control valves can be of different types.

Manufacturers produce the following types of products:

- Steam-water products for media with different pressure and temperature. This equipment is installed on water pipes and ventilation systems. In addition, it is allowed to use such fittings for drowning.

- Energy structures for high-pressure steam pipelines.

- Gas models characterized by the maximum level of tightness.

- Oil varieties resistant to corrosion.

- Chemical locking elements. This type of reinforcement has a high resistance to concentrated chemicals.

- Marine products that are not afraid of sea water and pitching. Similar products are used in the construction of ships and ports.

- Tank models. Unlike all the previous ones, tank structures have only one branch pipe. They are equipped with a container of arbitrary volume and purpose.

Equipment Characteristics

When choosing these structures, you need to clearly understand what the fittings should provide and what tasks you will have to cope with.

Main product features:

- Permissible pressure of the medium. For example, the pressure in the water supply in the apartment does not exceed 1.6 MPa.

- The temperature of the medium.

- The diameter of the passage and the dimensions of the pipes.

- Corrosion resistance.

- Type of drive.

- Materials and method of production.

The shut-off and control valves are made of steel and cast iron. Its body is formed by forging, welding, casting or stamping. Often these methods are combined.

Types of fittings

If we take into account the classification by purpose, then these constructions can be divided into:

- Shut-off valves, allowing to completely stop the movement of the medium. Such constructions are used in case of pipeline repair or replacement of its individual sections.

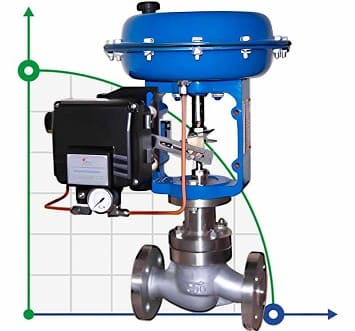

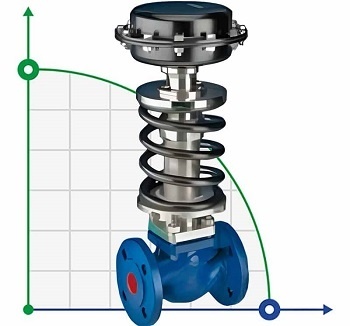

- Shut-off regulating valves. These products can not only block the flow, but also adjust the optimal pressure of the medium.

- Shut-off reverse valves. With the help of these models, they block the flow and prevent it from passing in the opposite direction.

In addition to the purpose, these devices differ from others by the principle of operation of the regulating element. Let's consider what is the locking mechanism:

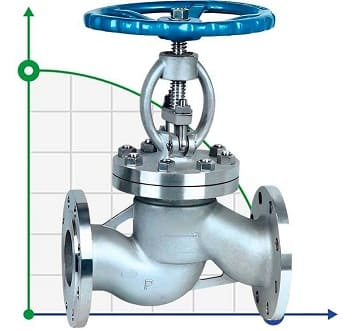

- Flaps In such blocks, the adjusting element moves at right angles towards the flow.

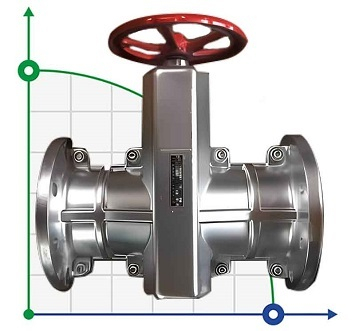

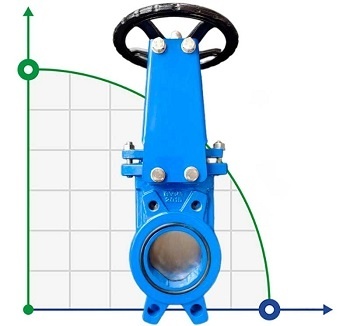

- Valves. Unlike flaps, valves have a gate mechanism that moves parallel to the moving medium.

- Faucets and taps. These pipeline components are equipped with a rotating control element.

- Disc shutters. The disk also rotates around its axis. It can pass perpendicular to the flow or at an angle to it.

Methods of connecting shut-off devices

When buying this equipment, it is important to be guided in its classification: to know what applies to shut-off devices and how they are connected to the pipeline. These constructions can be executed:

- Flangeless. Such models do not have their own flanges and can be connected to a pipe with flanges. The installation is carried out by welding.

- Interflanged. These products also do not have flanges. Reflecting on the question of what they are needed for, you can get an answer by immediately familiarizing yourself with the purpose of flangeless products. Most often, such devices are used as connecting elements.

- Coupling. Such mechanisms are equipped with threaded nozzles that are located on the inner shell of the product.

- Welded. These pipeline elements have cylindrical bends along the edge. They are welded to pipes or other equipment.

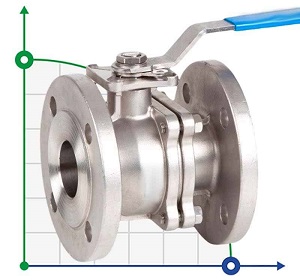

- Flanged. Flanges mean discs with holes on the edges of the products. Such discs are bolted to the flanges on the connected pipes.

- Threaded-end. Such products are equipped with cylindrical taps with threads.

- Fitting, having pipes with an external thread.

In order to connect the elements correctly, you need not only to know what a particular mechanism is for, but also to use appropriate sealing materials. The pipeline seal can be sealless, membrane, stuffing box or bellows.

It is necessary to choose the seal material taking into account the scope of application, the characteristics of the system and the characteristics of the medium being transported through the pipeline.

| Connection diameter, DN | 250 |

| Producer | BTS Engineering |

| Operating temperature | -60°C + 260°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 80 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 40 |

| Producer | BTS Engineering |

| Operating temperature | -60°C + 260°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 150 |

| Producer | BTS Engineering |

| Operating temperature | -60°C + 260°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 125 |

| Producer | BTS Engineering |

| Operating temperature | -60°C + 260°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 32 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 200 |

| Producer | BTS Engineering |

| Operating temperature | -60°C + 260°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 50 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 65 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

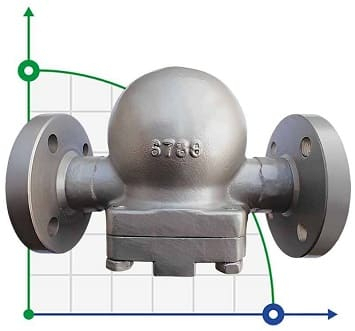

| Connection diameter, DN | 80 |

| Producer | BTS Engineering |

| Material | cast iron |

| Max.temperature, C | 120 |

| Nom.pressure, Mpa | 1,6 |

| Connection diameter, DN | 40 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 65 |

| Producer | BTS Engineering |

| Operating temperature | -60°C + 260°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 40 |

| Producer | BTS Engineering |

| Operating temperature | 0°C + 120°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 125 |

| Producer | BTS Engineering |

| Operating temperature | 0°C + 120°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 150 |

| Producer | BTS Engineering |

| Operating temperature | 0°C + 120°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 200 |

| Producer | BTS Engineering |

| Operating temperature | 0°C + 120°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 65 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 32 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 50 |

| Producer | BTS Engineering |

| Operating temperature | 0°C + 120°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 50 |

| Producer | BTS Engineering |

| Operating temperature | ≤300 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 80 |

| Producer | BTS Engineering |

| Material | AISI 304 stainless steel |

| Max.temperature, C | 130 |

| Nom.pressure, Mpa | 1,6 |

| Connection diameter, DN | 50 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 40 |

| Producer | BTS Engineering |

| Operating temperature | ≤150 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 250 |

| Producer | BTS Engineering |

| Operating temperature | 0°C + 120°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 250 |

| Control signal, mA | 4-20 |

| Producer | BTS Engineering |

| Explosion protection | Yes |

| Operating temperature | -60°C + 260°C |

| Connection diameter, DN | 200 |

| Control signal, mA | 4-20 |

| Producer | BTS Engineering |

| Explosion protection | Yes |

| Operating temperature | -60°C + 260°C |

| Connection diameter, DN | 350 |

| Producer | BTS Engineering |

| Operating temperature | 0°C + 120°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 40 |

| Producer | BTS Engineering |

| Operating temperature | ≤300 |

| Nom.pressure, Mpa | 1,6 |

| Connection type | flanged |

| Connection diameter, DN | 80 |

| Producer | BTS Engineering |

| Operating temperature | -60°C + 260°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |

| Connection diameter, DN | 65 |

| Producer | BTS Engineering |

| Operating temperature | 0°C + 120°C |

| Nom.pressure, Mpa | 1,6 |

| Connection type | interflange |