- Home

- Mechanical sealsMechanical seals by typeMechanical seal for the pumpMechanical seals by brandShaft runout seal for agitators, hoppers and conveyorsRepair of mechanical seals, friction pairsManufacturing of cuffs, rings, oil sealsManufacturing of parts from silicon carbide, zirconium silicateInsulator bearing protection Bearing defender isolator

- Insulator bearing protection Bearing defender isolator

Insulator bearing protection Bearing defender isolator

Insulator bearing protection Bearing defender isolator for gearbox, pump, conveyor, agitator, mixer, special equipment.

Bearing defender isolator The bearing insulator (bearing protector) is installed in place of the cuff, it is a kind of non-contact, wear-resistant, permanent device for protecting the bearing from moisture, water, dirt, ingress of working fluid in pumps into the bearing chamber, bearing assembly, steam.

Bearing defender isolator bearing insulator does not wear out will be used in severe operating conditions for agricultural machinery and mechanisms, wheel reducers, hubs, industrial mechanisms, pumps for the food industry IP 67, special-purpose equipment for off-road, operated with increased influence of the external or technological environment.

The sizes of isolators

Traditionally, an oil seal cuff is installed, of different sizes and materials that can withstand temperatures, environments, friction loads, but the only drawback is that when moisture, water, dirt and dust enter, the cuffs fail and leak, pass through. The oil or grease of the bearings is contaminated or leaks occur, which leads to the failure of the bearing, shaft, gear, mechanisms whose repair or replacement, as well as downtime of equipment brings losses to the enterprise.

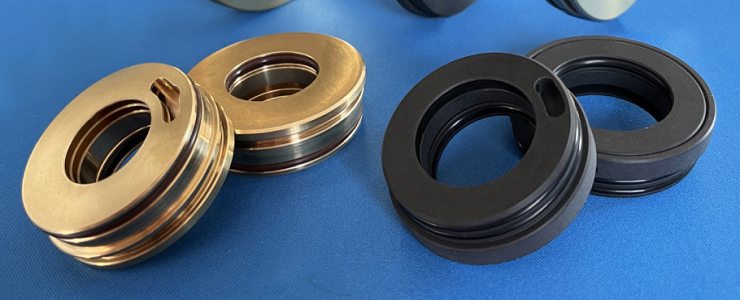

It consists of a rotor and a stator, which are united by an O-ring, so that the two parts will not be separated during operation. These two components interact to keep external contaminants out of the bearing housing and also prevent lubricants from leaking.

The tightness of the bearing insulator will not deteriorate over time, which will allow it to provide lifetime protection of bearings for rotating equipment.

Features of the Bearing insulator

- Contactless, without shaft wear - unlike traditional cuffs.

- Zero energy consumption, minimal friction expenses.

- It blocks the moisture insertion.

- The shaft rotation speed is to 60 m/s.

- The durability - 40 000 hours.

- Easy servicing.

- The temperature range: -35 ℃~204 ℃.

- The seperable construction is available.

The results of bearing destruction, caused by using the wrong seal:

- 40%–80% Breakage of the pump, reducer, destruction of a nave, wear of an axis or a shaft;

- 50% - the contamination of the pumped or transported product;

- 70% - the insertion of moisture in electric motor wrap.

How to prolong the service life

90 % of bearings cannot reach the expectable durability of exploitation because of containments and lubricant leakage.

Individual design

The unique engineering capability of bearing isolators construction in combination with many years of practical experience of work in industrial rotation equipment can be widely used in pumps, motors, reducers, fans, screw conveyors, etc.

Improving the reliability of equipment

% water mixed with lubricants can lead to 48% bearing wear.

Patented structure.

Double oil ducts and two-channel design to prevent the dust, Bearing defender isolator can provide the real zero leakage, protection from wearing, and high capacity of seal in critical conditions.

- Different constructions for splashing, immersion or forced oil lubrication;

- special construction for the high and low speed of shaft rotation;

- it fits for exhausted shaft, does not need the technical service;

- do not allow the insertion of moisture in the bearing body during the stop and cooling.

The application in pumps

- the choice of the seal is set by API610 standard;

- ISO, technological pump ANSI, centrifugal pump, vacuum pump, screw pump, multistage pump;

- individual design and the absence of the need to modify the case;

- different constructions for different lubricant conditions.

Application in bearing joints and blocks

- Applicable for roller bearings, bushing bearings and magnetic bearing blocks;

- the special design can adapt to the big movement of a shaft;

- replace the simple labyrinth seal without making any changes to the housing design;

- the seperable construction is available.

Materials of isolators

- Stainless steel rotor with bronze stator bearing isolator improves the anti-corrosion characteristics.

- The production in PTFE clean material regarding FDA certificate.

- Isolator made of stainless steel, used for corrosion conditions, when bronze isn't suitable.