- Home

- Engineering services and equipmentVacuum evaporation plant Decanter centrifuges, separatorsCrushers for grinding cereal crops in the process of feed, flour, ethanol productionControl and measuring instruments, sensors, flow meters for production automationDesign, construction of a distillery, distillationSpiral shell and tube heat exchangerIndustrial dryersSolid fuel boilersEnzymes, alcohol yeast, antiseptics for the production of alcoholEnergy auditSteam industrial boilers

- Design, construction of a distillery, distillation | page: 3

Design, construction of a distillery, distillation | page: 3

Projects for alcohol plant, bioethanol, biofuel, DDGS. The construction of bioethanol plants, turn-key construction of the plant, engineering of reversed water supply, SPS – Sewage Pumping Stations.

- Microfiltration, nanofiltartion, ultrafiltration.

- Valve trays, bubble-cap trays, sieve deck trays, perforated trays.

- Equipment for the alcohol plants.

- Ex pumps (explosion-proof pumps), chemical pumps, pumps for CIP, pumps for evaporating apparatus, pumps for concentrate, pneumatic pumps, chemical pumps, pumps with magnetic coupling, spiral heat exchangers, recuperative heat exchangers, recuperative spiral heat exchanger, heat exchangers for chemicals, spiral heat exchangers for oil, for mash wort, fermentable wort.

- Distillation column, epuration column, rectification column, the column of the final clearance, booster column, fusel column, distillation system.

- The drying of fermentable wort, decanter centrifuge, separator, heat-exchangers, dephlegmator, immersion heater.

- Plunger pumps, fermentable wort pumps, alcohol pump, centrate pump, regular packing.

- Tower packing.

- Pall rings, Rashig rings.

- Ceramic balls, zeolite.

- Intalox packings.

- Cascaded ring, metal cascaded packing, alumina balls, ceramic packing.

- Regular packing.

- The repair of the pump equipment, mechanical seals for pumps.

BTS-ENGINEERING carries out design, manufacture, installation, commissioning and automation brew-rectification plants (BRU).

BTS-ENGINEERING - a manufacturing company with many years of practical experience in development, production and implementation of various types of equipment for various factories in the food industry.

Possibilities for the manufacture of both standardized and non-standard equipment for all industries industry according to the design documentation of the Customer, or according to the documentation developed by our company for on the basis of the technical assignment of the Customer and in accordance with new construction technologies.

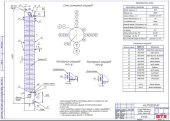

Column apparatus

Columns are designed to carry out heat and mass transfer processes in technological installations of chemical, petrochemical, oil refining, oil, gas, pharmaceutical, food and other industries.

Manufactured according to technical projects and design documentation.

Materials: carbon steel, stainless steel, special alloys, titanium, aluminum.

Column apparatus is subdivided into types:

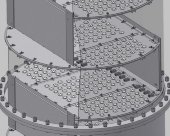

Cymbal design:

Column Equipment | Column type apparatus

Mast column

In mash-rectification plants, the purpose of the mash column is to completely distill alcohol from the mash with impurities accompanying ethanol, that is, to separate the volatile part of the mash from the non-volatile.

Distillation column

Distillation column - designed for the separation of liquid mixtures, the components of which have different boiling points. The distillation column is a vertical cylinder with contact devices inside.

Column epuration

The epuration column is designed to separate highly volatile impurities from the brew distillate.

| Valve thickness, mm | 2 |

| Number of valves, pcs | 48 |

| Relative free passage area, % | 7,76 |

| Producer | BTS Engineering |

| Material | AISI 321 |

| Valve thickness, mm | 2 |

| Number of valves, pcs | 48 |

| Relative free passage area, % | 7,76 |

| Producer | BTS Engineering |

| Material | AISI 321 |

| Valve thickness, mm | 2 |

| Producer | BTS Engineering |

| Material | AISI 321 |

| Max.temperature, C | 200 |

| Diameter, mm | 1 600 |

| Valve thickness, mm | 2 |

| Producer | BTS Engineering |

| Material | AISI 321 |

| Max.temperature, C | 200 |

| Diameter, mm | 1 500 |

| Producer | BTS Engineering |

| Material | AISI 321 |

| Max.temperature, C | 200 |

| Diameter, mm | 1 400 |

| Distance between button mm | 340 |

| Producer | BTS Engineering |

| Material | AISI 304 stainless steel |

| Capacity of the colum | 3000-4000 |

| Button type | EDV |

| Diameter, mm | 1 400 |

| Productivity of the finished product, t/h | 1 |

| Producer | BTS Engineering |

| Pressure | 2 MPa |

| Productivity of the finished product, t/h | 1 |

| Producer | BTS Engineering |