- Home

- Industrial pumps

- Pumps by manufacturer

- Hydro-Vacuum

- Liquid ring single-stage vacuum pumps PW1 Hydro-Vacuum

Liquid ring single-stage vacuum pumps PW1 Hydro-Vacuum

Single-stage liquid ring vacuum pumps PW1 Hydro-Vacuum designed for suction and pumping of dry gas with temperatures up to 150 °C and vapor-saturated gases, characterized in that their temperature does not exceed 100 °C, with the possibility of using working fluids with a viscosity of up to 60 mm² /s and a density of 800 - 1200 kg /m³ , the water temperature at the outlet of the pump must not exceed 80 °C. Hydro-Vacuum manufactures single-stage and two-stage liquid ring vacuum pumps, the PW series.

Vacuum pumps

In pumps of the PW series, the pump and the motor are mounted on a common support. The torque from the engine is transmitted to the impeller through a shaft mounted in the support bearings and an elastic coupling. This design makes the vacuum pump noticeably longer and heavier, but it makes it much easier to maintain when the pump needs to be disassembled or the engine needs to be replaced. In addition, the pump is mounted on 2 supports (impeller between bearings) which gives a much longer service life of the pumps than a monoblock (mounted on the motor shaft or impeller seat) capacity from 24 m³/h to 1500 m³/h and maximum residual pressure up to 33 mbar.

Characteristic table

| Model | QR-Production m³/hour | PS- Suction pressure, mbar | P - Electric motor power, kW | Dimensions (LxWxH), mm | Weight, kg |

| PW1.12 | 24.0 | 33 | 1.1 | 678x240x250 | 47.4 |

| PW1.13 | 54.0 | 33 | 1.5 | 742x240x250 | 51.0 |

| PW4.11 | 75.0 | 33 | 3.0 | 924x315x410 | 105.0 |

| PW4.12 | 120.0 | 33 | 4.0 | 967x315x410 | 121.0 |

| PW4.13 | 190.0 | 33 | 5.5 | 1103x342x493 | 169.0 |

| PW4.14 | 240.0 | 33 | 7.5 | 1143x342x493 | 190.0 |

| PW5.12 | 315.0 | 33 | 11.0 | 1190x415x608 | 273.0 |

| PW5.13 | 395.0 | 33 | 15.0 | 1277x415x608 | 300.0 |

| PW5.14 | 460.0 | 33 | 15.0 | 1317x415x608 | 309.5 |

| PW7.11 | 600.0 | 33 | 18.5 | 1925x640x735 | 777.0 |

| PW7.12 | 800.0 | 33 | 30.0 | 2060x665x735 | 886.0 |

| PW7.13 | 1150.0 | 33 | 37.0 | 2210x700x948 | 1171.0 |

| PW7.14 | 1500.0 | 33 | 45.0 | 2390x750x948 | 1305.0 |

Scope of vacuum liquid ring pumps

- Chemical industry;

- pharmaceutical industry;

- food industry;

- Pulp and paper production;

- Textile industry;

- Filling of centrifugal pumps and siphons;

- Production of bricks and cement;

- Foundry;

- Woodworking industry.

Design features of vacuum liquid ring pumps Hydro-Vacuum

The pumps are designed and manufactured in accordance with the ISO 9001 standard. All manufactured pumps undergo comprehensive checks and tests at the company's stands. A wide range of materials used for the manufacture of vacuum pumps.

| Pump Parts | Compressor type | Material version "d" | |||||

| 1 | 3 | 4 | 5 | 6 | 7 | ||

| Corps | PW/DW.1 PW/DW.4 PW/DW.5 PW/DW.7 | gray cast iron | gray cast iron | chrome cast iron | tin bronze | carbon cast steel | austenitic cast steel |

| Seal housings | PW/DW.1 PW/DW.4 PW/DW.5 PW/DW.7 | gray cast iron | gray cast iron | chrome cast iron | tin bronze | carbon cast steel | austenitic cast steel |

| Suction-discharge units | PW/DW.1 PW/DW.4 PW/DW.5 | gray cast iron | gray cast iron | chrome cast iron | chrome cast iron | carbon cast steel | austenitic cast steel |

| Distance links | PW/DW.7 | gray cast iron | gray cast iron | chrome cast iron | tin bronze | carbon cast steel | austenitic cast steel |

| Rotors | PW/DW.1 | tin bronze | carbon cast steel | special austenitic cast steel | tin bronze | tin bronze | special austenitic cast steel |

| PW/DW.4 PW/DW.5 | austenitic cast steel | carbon cast steel | austenitic cast steel | ||||

| PW/DW.7 | brass | ||||||

| Shaft | PW/DW.1 PW/DW.4 PW/DW.5 PW/DW.7 | stainless steel | stainless steel | acid-resistant steel | acid-resistant steel | stainless steel | acid-resistant steel |

| Throttle | PW/DW.1 PW/DW.4 | itamide | itamide | itamide | itamide | - | - |

| PW/DW.7 | gray cast iron | gray cast iron | chromium chavoon | chromium chavoon | carbon cast steel | austenitic cast steel | |

Cast iron cast bed. Complete set of pumps with various types of seals, depending on the needs of the client:

- Soft cord seal #6498;

- Mechanical seal "ANGA" 43А1;

- Mechanical seal "Crane"2100.

Various protective coating options for the product:

- standard;

- Special;

- Marine;

- Export tropic dry;

- Export tropic wet.

Possibility to choose the scope of supply:

- Pump with free shaft end;

- Clutch pump;

- Pump with coupling and base plate;

- Completeness 3 plus electric motor.

Availability of spare parts even after decades of operation. Warranty period 24 months.

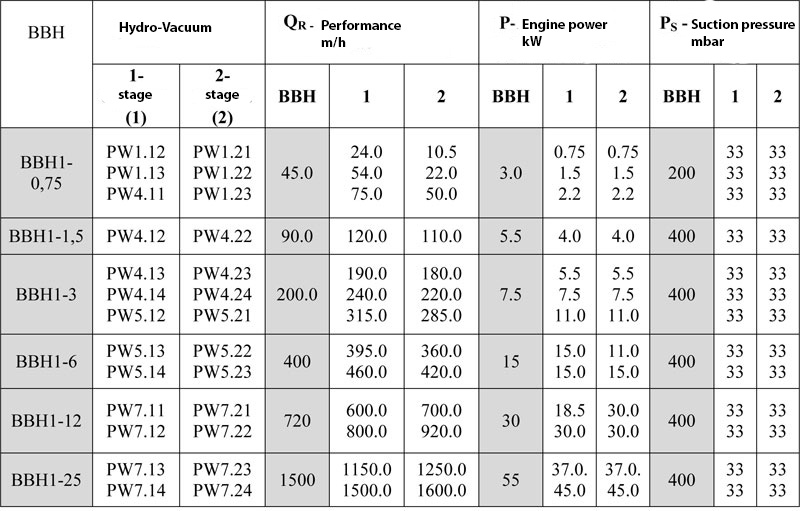

Table of operating parameters of single-stage liquid ring vacuum pumps PW.1.12 - PW7.14

Regardless of the operating mode (PB or PZ), vacuum pumps must have a secure supply of working fluid in the quantities indicated in the PB operating mode column. When using water as a working fluid, it is recommended to use chemically treated water to limit the amount of precipitation deposited on the walls of the product. Precipitation leads to rapid wear of all jointly working rubbing elements of machines. It is recommended to use water with a hardness of approx. 40n for two-stage and approx. 80n for single-stage vacuum pumps.

Table of interchangeability of vacuum liquid ring pumps VVN and vacuum pumps PW

Advantages of vacuum pumps Hydro-Vacuum of the PW series in comparison with vacuum pumps of the VVN series:

- Possibility of using single-stage and two-stage vacuum pumps, depending on the requirements of the technological process;

- High vacuum level (up to 33 mbar.abs);

- Possibility of completing with a reservoir, selected for closed systems of supply of working fluid (water saving);

- Wide choice of constructive materials;

- Possibility of completing different types of seals;

- Large range of vacuum pumps;

- Use of electric motors with less power;

- Possibility to choose the completeness of delivery;

- Full technical support for the client.

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 24 |

| Power capacity, kW | 1,1 |

| Material | cast iron |

| Rate of turn, rpm | 3 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 24 |

| Power capacity, kW | 1,1 |

| Material | cast iron |

| Rate of turn, rpm | 3 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 53 |

| Power capacity, kW | 1,5 |

| Material | cast iron |

| Rate of turn, rpm | 3 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 53 |

| Power capacity, kW | 1,5 |

| Material | cast iron |

| Rate of turn, rpm | 3 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 75 |

| Power capacity, kW | 3 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 75 |

| Power capacity, kW | 3 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 120 |

| Power capacity, kW | 4 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 120 |

| Power capacity, kW | 4 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 190 |

| Power capacity, kW | 5,5 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 190 |

| Power capacity, kW | 5,5 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 240 |

| Power capacity, kW | 7,5 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 240 |

| Power capacity, kW | 7,5 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 315 |

| Power capacity, kW | 11 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 395 |

| Power capacity, kW | 15 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 460 |

| Power capacity, kW | 15 |

| Material | cast iron |

| Rate of turn, rpm | 1 500 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 600 |

| Power capacity, kW | 18,5 |

| Material | cast iron |

| Rate of turn, rpm | 1 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 600 |

| Power capacity, kW | 18,5 |

| Material | cast iron |

| Rate of turn, rpm | 1 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 800 |

| Power capacity, kW | 30 |

| Material | cast iron |

| Rate of turn, rpm | 1 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 800 |

| Power capacity, kW | 30 |

| Material | cast iron |

| Rate of turn, rpm | 1 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 1150 |

| Power capacity, kW | 37 |

| Material | cast iron |

| Rate of turn, rpm | 1 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 1150 |

| Power capacity, kW | 37 |

| Material | cast iron |

| Rate of turn, rpm | 1 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 1500 |

| Power capacity, kW | 45 |

| Material | cast iron |

| Rate of turn, rpm | 1 000 |

| Producer | Hydro-Vacuum |

| Pump capacity, m3/h | 1500 |

| Power capacity, kW | 45 |

| Material | cast iron |

| Rate of turn, rpm | 1 000 |