- Home

- Industrial pumps

- Pumps by manufacturer

- WILOWilo-Drain TSW stainless steel submersible pumpWilo-Drain TMW submersible pump for drainage water drainagePB booster pumpMVI vertical high pressure pumps HELIX FIRST, MVIHorizontal high pressure pumps MEDANA, MHIWell pumps Wilo-Sub TWI 5, TWI 5-SE, TWI 5-SE PNPWILO CronoNorm NL cantilever pumpsWilo-DrainLift KH, TMP Pressure plants for wastewater disposalPumping station Wilo-Jet HWJ with a hydraulic accuHigh pressure glandless pumps MVISSubmersible pumps Wilo-Drain MTS for wastewater diSelf-priming centrifugal pumps Wilo-Jet WJFire extinguishing system Wilo-SiFire ENSpecial IPH pumps for superheated water and thermal oilWilo-FLA-2 pressure boosting systemSewage pumps Wilo EMU FAWILO TOP-S Glandless Circulation PumpsCirculation pumps for heating systems and underflo

- Sewage pumps Wilo EMU FA

Sewage pumps Wilo EMU FA

Submersible sewage pump with dry rotor motor. Submersible sewage pump for sewage with a motor as a block unit, suitable for flooding for stationary and mobile installation in submerged and non-submerged state. Mobile installation is possible depending on the type.

Designation

| For example hydraulics: | Wilo-EMU FA 08.34E |

| FA | Submersible sewage pump with motor |

| 08 | x10=nominal diameter of the pressure connection, e.g. DN80 |

| 34 | Rated power number |

| E | Impeller type |

| For example, a motor: | Wilo-EMU T 17.2-4/24K Ex |

| T | Motor version |

| 17 | Standard size |

| 2 | Conditional number |

| 4 | Number of poles |

| 24 | x10=bag length [mm] |

| K | Seal design |

| Ex | Explosion protection approval |

Specifications

- Mains connection: three-phase mains, 400 V, 50 Hz.

- Immersion mode: S1.

- Non-immersed operating mode with self-cooling motor: S1.

- Protection class: IP 68.

- Max. temperature of the pumped-over liquid: 3 & dash; 40 °С, higher temperature on request.

- Seal: depending on the motor with lip seal and mechanical seal, two with sliding mechanical seals or one block seal cassette.

- Free passage: 45 - 130 mm.

- Continuously lubricated rolling bearings.

- Max. immersion depth 20 m.

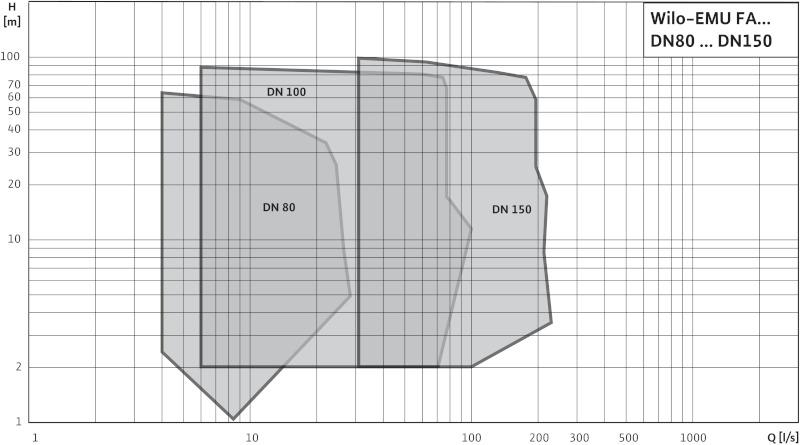

Performance characteristics

Product Features/Benefits

- Stationary and mobile, immersed and non-immersed;

- Full immersion;

- Easy installation thanks to suspension device or pump support foot;

- Specialist. materials and coatings against abrasion and corrosion;

- Longitudinally watertight cable routing (depending on the motor);

- Adjustment of the duty point by rotating the impeller.

Application

- Pumping wastewater containing faeces in wastewater treatment plants and pressure water disposal systems;

- Sewerage of populated areas and drainage facilities and drainage of household drinking water;

- Construction and industrial use.

Hydraulics

The outlet from the pressure side is made in the form of a horizontal flange connection. Maximum allowed content dry matter is, depending on the type of hydraulics and impeller, max. 8 %.

The following impeller types are used:

- Free-vortex impeller (W);

- Single-vane impeller (E);

- Two-vane impeller (Z);

- Three-bladed wheel (D).

Single and multi-vane hydraulics (Z, D) are equipped with a rotating and separating ring (depending on the type). They help to ensure that the productivity of the unit remains at the same level for a long time.

Motor

Dry pump motors (T motor) transfer their waste heat directly to the housing parts into the surrounding pumped medium and can be used immersed in continuous exploitation. Depending on their dimensions, they can be operated in a short-term operating mode and in a mode continuous operation also without immersion.

Oil-filled motors (FK motor) and self-cooling dry-rotor pump motors (FKT, HC motor) give its heat through the built-in heat exchanger into the pumped medium. Therefore, these motors are suitable for continuous wet and dry operation and dry well installation.

All motors have a compression chamber to protect the motor from the pumped medium. It is also available can be monitored externally and optionally using a compression chamber electrode.

All types of filling media used are biodegradable and environmentally friendly.

Motor cable feedT,HC andFKT waterproof. Cable for motors of size 17 are supplied in a fixed multiple of 10 m. From motor size 20, the length is cable is selected separately for each specific case.

Sealing

Depending on the type of motor, the following seal options are available on the pumped medium side and on the side motor:

- Option H: on the side of the pumped medium with mechanical seal, on the side motor - with two radial lip seals;

- Option G: two mechanical seals of independent action;

- Option K: block sealing cassette with two mechanical seals independent action.