- Home

- Industrial pumps

- Pumps by liquidsBitumen pumpsEx pump for draining bilge liquidsNitric acid pumpPump for dosing hypochlorite, chlorinePump for liquid glassPump for fatPump for potassium bichromate, caustic sodaPump for cream and pastePump for fish and seafoodPump for syrupSour cream pumpPump for hydrocarbonsPump for minced meatPump for chocolate and massPump for emulsions and suspensionsPump for spice and saltPump for cheese grainPump for the extractPumps for ammonia water, ammonium hydroxide NH4OHPumps for stillage, mashWine pumpsWater pumpsPumps for viscous liquidsPumps for hexaneGlycerin pumpsLiquid feed pumpsPumps for UANPumps for ceramic slipAcid pumpsGlue pumpsPumps for paints and varnishesFuel oil pumpsMilk pumpsPumps for an ice creamPumps for urea, liquid fertilizers, ammoniaPumps for petroleum products, gasoline, diesel fuelMolasses pumpsSuperheated water pumpsPermeate PumpBeer pumpsChemical dosing pumpsPumps for giblets and slaughter wasteVegetable oil pumpsResin pumpsPumps for pumping alcohol ЕХSewage and sewage pumpsFertilizer pumpsPumps for freonSlurry pumpsLye pumpsEthylene glycol pumpsAcid-resistant pumps for aggressive liquidsThermal oil pumps +350Food pumps for juice, concentrate

- Bitumen pumps

Bitumen pumps

To select a pump for bitumen in terms of capacity and performance for pumping, it is necessary to take into account the characteristics of bitumen, viscosity, temperature. Bitumen is composed of complex hydrocarbons and contains elements such as calcium, iron, sulfur and oxygen.

The quality of the material and the ease of production depend on the source and type of crude oil from which it is obtained. Bitumen is commonly used in industry. It was first used because of its natural adhesive and waterproofing properties, which help to bond building materials together.

- Steel working parts and increased clearances depending on toughness.

- Bronze bushings can be used at temperatures up to 232 °C. Carbon-graphite is used at temperatures above 232 °C. Note: High temperature graphite may be required for some pump sizes.

- Optimal shaft seals:

- stuffing box packing;

- flushed cartridge lip seal;

- single mechanical seal with hard surfaces metal bellows and flush;

- double mechanical seal with hard surfaces (internal), metal bellows and barrier liquid supply.

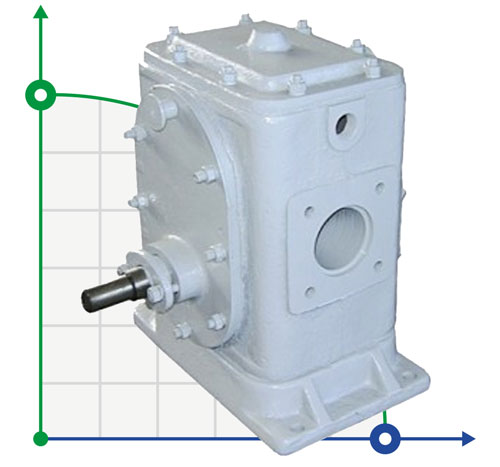

Pump DS - 125

- Delivery: 30 cbm/hour

- Head: specify

- Power: check

- RPM: 1500

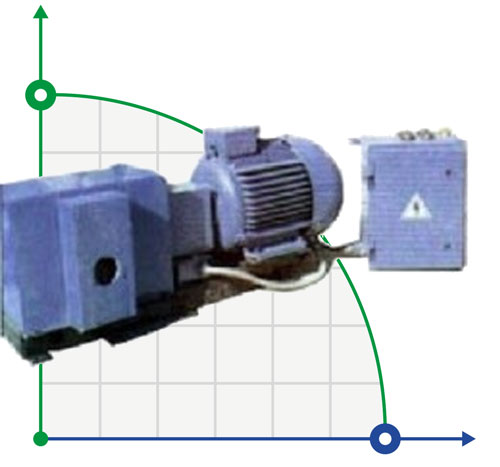

Pump DS - 134

- Delivery: 30 cbm/hour

- Aggression: specify

- Power: 11 kW

- RPM: 1500

CO pump - 194

- Delivery: 6 cbm/hour

- Head: 50 m.w.

- Power: 7,5 kW

- RPM: 1500

Selection by parameters

Producer: BTS EngineeringClear

Pre-order only

Vendor code: 15542

| Producer | BTS Engineering |

| Pump capacity, m3/h | 6 |

| Power capacity, kW | 2,2 |

| Output pipe diameter | 40 mm |

| Rate of turn, rpm | 1 450 |

$3,507

Pre-order only

Vendor code: 15543

| Producer | BTS Engineering |

| Pump capacity, m3/h | 8 |

| Power capacity, kW | 3 |

| Input pipe diameter | 50 mm |

| Output pipe diameter | 50 mm |

$4,055

Pre-order only

Vendor code: 15544

| Producer | BTS Engineering |

| Pump capacity, m3/h | 25 |

| Power capacity, kW | 7,5 |

| Input pipe diameter | 80 mm |

| Output pipe diameter | 65 mm |

$4,958

Pre-order only

Vendor code: 15545

| Producer | BTS Engineering |

| Pump capacity, m3/h | 52.5 |

| Power capacity, kW | 15 |

| Input pipe diameter | DN100 |

| Output pipe diameter | DN100 |

$5,292

Pre-order only

Vendor code: 1043745

| Producer | BTS Engineering |

| Pump capacity, m3/h | 30 |

| Feed height, m | 60 |

| Input pipe diameter | 80 mm |

| Output pipe diameter | 80 mm |

Price on request