- Home

- Internal devices of columns and apparatuses

- Molecular sieve

- Molecular sieve 3A

Molecular sieve 3A

A 3A molecular sieve is a material used to adsorb molecules with a kinetic diameter of less than 3A. It does not interact with larger molecules, which allows this substance to be used for industrial purposes and cleaning. The sieve is mainly used for water adsorption. The substance has pores, a light gray color and comes in the form of spheres or granules. A special feature of using this screen is the possibility of re-regeneration by heating or reducing the pressure in the system. The reaction rate of the molecular sieve is very high, which allows you to quickly and efficiently process large volumes of products.

Advantages of using a 3A molecular sieve

The 3A molecular sieve has better conductive properties, which allows it to pass mixtures quickly and efficiently. 3A is characterized by good molecular selectivity, high resistance to deformation and breakage. In addition, the sieve is highly protected from contamination, which also increases the productivity of using this substance in systems.

All products pass a series of checks before going on sale. This allows you to improve the quality of the molecular sieve and distribute only the best product to users, which will serve for a long time, regenerate well and fulfill its basic properties.

Areas of use of the 3A molecular sieve

The 3A molecular sieve is used to achieve industrial goals in many areas of human life. The most popular methods of using the substance are:

- Draining liquids and unsaturated carbohydrates;

- Gas dehumidification;

- Dehumidification of high-polar compounds;

- Liquid alcohol dehumidification;

- Dehydration of double-glazed windows that are filled with water or air.

In addition, it can be used for drying kerosene or jet fuel, acetylene, propylene, ethylene or natural gas. In any case, it is better to store the substance in a closed container and not allow it to interact excessively with open air, since the reaction may begin ahead of schedule.

Before you buy a 3A molecular sieve, it is better to consult our specialists. We will be happy to help you choose the right product, as well as provide you with all the necessary information about the range of our website.

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 20 ± 10 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 60 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Average particle size, d, μm | 4 ± 2 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 98 ± 1 |

| Bulk density, g/l | 350 ± 100 |

| Producer | BTS Engineering |

| Nozzle type | Molecular Sieve |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Producer | BTS Engineering |

| Producer | BTS Engineering |

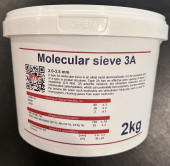

| Diameter, mm | 1,5-1,7 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | ≥600 |

| Wear ratio, % | ≤0,20 |

| Producer | BTS Engineering |

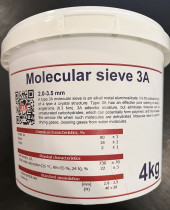

| Diameter, mm | 3,0-3,3 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | ≥600 |

| Wear ratio, % | ≤0,20 |

| Producer | BTS Engineering |

| Diameter, mm | 1,6-2,5 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | ≥650 |

| Wear ratio, % | ≤0,20 |

| Producer | BTS Engineering |

| Diameter, mm | 3-5 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | 750-780 |

| Wear ratio, % | ≤0,20 |