- Home

- Internal devices of columns and apparatuses

- Molecular sieve

- Molecular sieve 13X

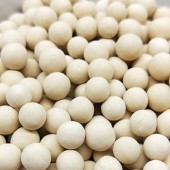

Molecular sieve 13X

Molecular sieve 13x is a special material used for the process of adsorption of molecules with a kinetic diameter of less than 9 Angstroms and the exclusion of those molecules that exceed this indicator.

Physically, the molecular sieve 13x is represented as an X-Type sodium crystal with characteristic, pronounced pores. Most often, such a filter is used to separate various gases, in particular, it can be the purification of nitrogen from oxygen. Due to its properties, sieve 13X can separate impurities in mixtures that are too large and cannot be filtered using Type A crystals.

The mass transfer rate of this molecular sieve, as well as its efficiency and productivity, is significantly higher than that of similar materials. Because of this, it is often used by manufacturers and suppliers to achieve commercial or utility purposes.

Scope of use molecular sieve 13X

Most often, like any other molecular sieve, 13X is used for adsorption of molecules, as well as their purification from various impurities. In particular, molecular sieve 13X can be used for:

- Air purification and filtration in air installations (molecular sieve 13x can effectively purify the air from water and CO2).

- Drying of natural gas, as well as liquefied carbohydrates or petroleum gases.

- Drying of various gases used by people.

- Oxygen production due to the adsorption process during sudden pressure drops in installations.

- Filtration of particles with a large kinetic diameter.

Additionally, all moisture from the sieve can be removed by heating it to a temperature of 250-300 degrees Celsius. In order to prevent carbon dioxide from entering the filtration system, you need to activate it before starting.

Before you buy a molecular sieve 13x, we recommend that you contact our specialists, who will be happy to provide all the necessary information about the material, and will also be able to choose the right substance according to your needs. Here you can buy not only sieves, but also all pumping and filtration equipment, as well as additional tools for servicing various systems.

| Ethylene adsorption, % | ≤18 |

| Producer | BTS Engineering |

| Diameter, mm | 3-5 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | ≥640 |

| Ethylene adsorption, % | ≤18 |

| Producer | BTS Engineering |

| Diameter, mm | 1,7-2,5 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | ≥640 |

| Ethylene adsorption, % | ≤18 |

| Producer | BTS Engineering |

| Diameter, mm | 3,0-3,3 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | ≥610 |

| Ethylene adsorption, % | ≤18 |

| Producer | BTS Engineering |

| Diameter, mm | 1,5-1,7 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | ≥610 |

| Hardness, N | 60 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 680 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 60 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 680 ± 70 |

| Producer | BTS Engineering |

| Hardness, N | 60 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 680 ± 70 |

| Producer | BTS Engineering |

| Average particle size, d, μm | 4 ± 2 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 98 ± 1 |

| Bulk density, g/l | 350 ± 100 |

| Producer | BTS Engineering |

| Nozzle type | Molecular Sieve |

| Producer | BTS Engineering |

| Diameter, mm | 4-8 |

| Nozzle type | Molecular Sieve |

| Pour density, kg/m3 | 640 |

| Country of Origin | China |