- Home

- Yeast for beer, alcohol, whiskey

Yeast for beer, alcohol, whiskey

Fermentation is the name of a microbiological process that is due to yeast. The essence is extremely simple: yeast uses various types of sugar as "fuel" - sucrose, fructose, glucose. By carrying out a chemical reaction, yeast fungi produce energy. This is fermentation. Its side effect is the release of carbon dioxide and ethyl alcohol (ethanol). However, such a side effect is only for the yeast itself in the process of their vital activity. For those who have taken the yeast fungus "into circulation", the production of ethanol is just the main process for which everything is being started. Without yeast, which carries out fermentation, it is impossible to prepare alcohol - neither weak nor strong. The exception is perhaps fermentation, which is based on the activity of not yeast, but mold fungi (mold), as in the case of sake. Even without a sterile laboratory at their disposal, anyone can get an alcoholic drink at home. To do this, it is enough to have the yeast itself and what they use as a basis.

Wine is obtained from the juices of berries and fruits, and beer and kvass are obtained from malt contained in cereals. Having obtained mash as a result of fermentation, it can be distilled - the result will be a stronger alcoholic drinks: vodka, cognac, whiskey and so on.

Varieties of yeast

Mankind knows hundreds of types of yeast that produce ethyl alcohol in the process of oxygen-free (anaerobic) fermentation. In particular, Saccharomyces cerevisiae (baker's yeast) are popular. They help to get alcoholic beverages. Moreover, the original baking yeast should not be confused with those used for the preparation of alcohol.

Strains that are used as baking powder for baking also trigger the fermentation process. Heat treatment eliminates the resulting alcohol, carbon dioxide gives the bread a spongy structure. With the help of such yeast, some moonshiners prepare mash based on sugar and other raw materials. However, it is almost impossible to get a high-quality drink using ordinary baking yeast.

There are plenty of other strains on the market that are much more suitable for making alcohol:

- Brewer's yeast is the basis for making beer, as well as grain brew (for example, for whiskey). Fermentation with their use is slower, and more alcohol is produced than when using baking yeast. The speed of the process and the production of alcohol are the main selection criteria for any variety.

- Wine yeast is already another strain. Their use increases the yield of alcohol, increases resistance to sulfur dioxide - another by-product. Using wine yeast, drinks with good organoleptic properties (pleasant taste, aroma) are obtained from fruit and berry juices.

- Alcoholic yeast (turbo yeast) got its name just because it works the fastest. It is from them that moonshine is most often prepared - strong alcoholic beverages.

Features of alcoholic yeast

In addition to the yeast fungus itself, the mixture contains nutrients for them - fermentation takes place faster. The strongest yeast strains that are tolerant to ethyl alcohol are selected. The goal is to make the process go faster, stable, providing a pleasant taste and aroma of the finished drink, subject to a number of conditions. The composition includes nutrients - due to them it is possible to maintain the desired level of nitrogen in the mash, as well as vitamin and mineral components. Thanks to this, yeast fungi provide full-fledged fermentation, creating the necessary conditions for the birth of drinks with good organoleptic properties.

In addition to the fungi themselves and the nutrient medium for them, alcoholic yeast for moonshine often includes an acidity regulator and a foam extinguisher - it is difficult to do without it when fermentation is at a high speed. To get a high-purity brew, you can buy yeast, which includes sorbents. Finally, you can pick up such alcoholic yeast, which are specially designed to produce drinks based on a particular brew: fruit, grain. For example, strains are produced for the production of vodka, calvados, whiskey. Due to the composition, fermentation of certain compounds is actively taking place, the organoleptic properties of the original raw materials are preserved.

Advantages of alcoholic yeast

Several advantages that characterize this type of yeast fungus distinguish it from other varieties:

- The fermentation period has been reduced. In order for complete fermentation to occur, when using baking, beer or wine yeast, it will take from a week to two months. But if you use alcohol, the fermentation period is often reduced to two or three days. There are some strains that do allow you to meet in one day.

- Tolerance to ethyl alcohol is increased. This is another reason to buy alcoholic yeast, especially for the preparation of strong drinks. Ordinary yeast fungus cannot withstand too high a level of ethanol in the brew. After all, alcohol is a poison, so a relatively low level of 12-14 degrees for brewer's yeast is already critical. Wine bottles are kept up to a 15-degree level. Alcoholic yeast continues to live and function up to 20-23 degrees. The final strength of the mash is regulated by changing the volume of the fungus and sugar, as well as the temperature.

- Sugars ferment better. The structure of the yeast fungus does not allow it to consume dextrin and some other sugars - for example, from raw materials containing starch. For example, there are residual sugars in beer, hence the density and characteristic taste of the drink. Alcoholic yeast is supplied with enzymes, thanks to which non-fermentable sugars are broken down. The final alcohol yield increases, which is helped by the mentioned tolerance of the fungus to alcohol.

- Modern alcoholic yeast produces drinks with good organoleptic properties and, moreover, quite clean. Often, people engaged in moonshine and the production of homemade alcohol criticize rapid fermentation for leaving the product tasteless and odorless, and nutrients, left partially idle, worsen the quality of the product. Fortunately, technology is evolving.

So today the best yeast provides a high quality drink. In addition, you can adjust their concentration, temperature, acidity and other parameters.

Selection and purchase of alcoholic yeast

Yeast fungus should not be perceived as something "all-purpose". After all, it not only ensures the production of ethyl alcohol. It also determines the taste and aroma of the resulting drink. This is influenced by the side compounds that are produced in the process.

These can be higher alcohols, esters, various types of acids, and so on. Such substances remain in small, sometimes microscopic doses, but thanks to them we distinguish alcoholic beverages not only by strength. And this, of course, is very important to take into account when deciding how to choose alcoholic yeast and what criteria to focus on.

The varieties presented on the market differ in their relation to organoleptic properties:

Yeast for moonshine

It turns out a distillate based on sugar, and the faster, the better. The mash should be neutral and clean. Almost any turbo yeast with universal characteristics, with nutrients, with an acidity regulator and a foam extinguisher will be useful. Sorbents absorb by-products with an unpleasant odor. The goal is to minimize the fermentation time.

Yeast for vodka

Organoleptic properties are important, but not essential. Since vodka is a rectifier, with sufficient skill it is possible to preserve the taste and smell of raw materials with starch content. Yeast should be clean and with recharge. The fermentation period should also not be too long.

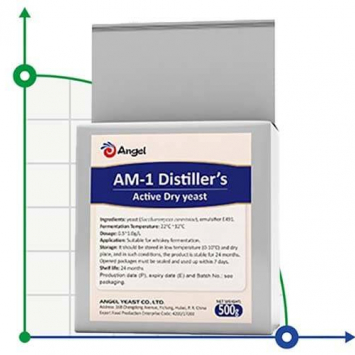

Yeast for grain brew

Side compounds that determine the taste and aroma of whiskey, as well as other beverages, are important here. The use of alcoholic yeast with special properties is important here. They are resistant to the influence of ethanol and heating. The fungi themselves and the nutrient medium are selected to create the taste and aroma of grain distillates. In the short phase before anaerobic fermentation, the risk of infection with mash is reduced.

Yeast for fruit brew

The taste and aroma of the raw materials are preserved. Due to fermentation, fruit distillate with good organoleptic properties is obtained. At the same time, wine yeast should be neutral, since the grapes already have everything necessary for fermentation.

| Permissible ethanol content in the brew | ≤17% (V/V) |

| Percentage of living yeast cells,% | ≥75 |

| Total amount of yeast, billion/g | ≥ 25 |

| Producer | Angel |

| Humidity,% | ≤6,5 |

| Optimal temperature | 32-34°С |

| Total amount of yeast, billion/g | ≥ 6 |

| Producer | Angel |

| Humidity,% | ≤6,5 |

| Operating temperature | 32-34°С |

| Optimal pH | 3.5-6.0 |

| Optimal temperature | 32-34°С |

| Permissible ethanol content in the brew | ≤ 23%(V/V) |

| Percentage of living yeast cells,% | ≥80 |

| Total amount of yeast, billion/g | ≥ 25 |

| Optimal pH | 3.8-4.5 |

| Operating pH | 3.8-4.5 |

| Optimal temperature | 32-35°С |

| Producer | ERBSLÖH |

| Operating temperature | 30-35°С |

| Dosage | 15-40 g/hl |

| Flocculation | high |

| Alcohol tolerance, % vol. | ≥15 |

| Producer | Angel |

| Operating temperature | 12-35°С |

| Dosage | 10-30 g/hl |

| Flocculation | high |

| Alcohol tolerance, % vol. | ≥18 |

| Conversion of sugar into alcohol | 1% alcohol (vol./vol.)/16.8 (g/l) |

| Glycerin production, g/l | ≥6 |

| Dosage | 15-25 g/hl |

| Flocculation | high |

| Alcohol tolerance, % vol. | until 18 |

| Producer | Angel |

| Operating temperature | 10-35°С |

| Dosage | 15-25 g/hl |

| Flocculation | high |

| Alcohol tolerance, % vol. | ≥18 |

| Producer | Angel |

| Operating temperature | 10-35°С |

| Dosage | 10-30 g/hl |

| Alcohol tolerance, % vol. | ≥ 14 |

| Conversion of sugar into alcohol | 1% alcohol (vol./vol.)/16.8 (g/l) |

| Glycerin production, g/l | ≥ 7 |

| Producer | Angel |

| Dosage | 15-25 g/hl |

| Flocculation | good |

| Alcohol tolerance, % vol. | ≥15 |

| Conversion of sugar into alcohol | 1% alcohol (vol./vol.)/16.8 (g/l) |

| Glycerin production, g/l | ≥6 |

| Dosage | 0.5 -1.0 g/l |

| Alcohol tolerance, % vol. | 18 |

| Live yeast cell | ≥10.0x10^9 CFU/g |

| Producer | Angel |

| Humidity,% | ≤7 |

| Dosage | 0.5 -1.0 g/l |

| Alcohol tolerance, % vol. | 15 |

| Live yeast cell | ≥10.0x10^9 CFU/g |

| Producer | Angel |

| Humidity,% | ≤7 |

| Optimal temperature | 18-22°С |

| Total amount of yeast, billion/g | ≥ 4,0 |

| Flocculation | medium to high |

| Alcohol tolerance, % vol. | 10 |

| Live yeast cell | ≥ 4.0х10^9 CFU/g |

| Optimal temperature | 10-15°С |

| Total amount of yeast, billion/g | ≥ 4,0 |

| Flocculation | high |

| Alcohol tolerance, % vol. | 10 |

| Live yeast cell | ≥ 4.0х10^9 CFU/g |

| Optimal temperature | 18-22°С |

| Total amount of yeast, billion/g | ≥ 4,0 |

| Flocculation | high |

| Alcohol tolerance, % vol. | 10 |

| Live yeast cell | ≥ 4.0х10^9 CFU/g |

| Optimal temperature | 18-22°С |

| Total amount of yeast, billion/g | ≥ 8,0 |

| Flocculation | average |

| Alcohol tolerance, % vol. | 14 |

| Live yeast cell | ≥ 8.0x10^9 CFU/g |

| Total amount of yeast, billion/g | ≥ 8,0 |

| Dosage | from 50 to 100 g/hl |

| Flocculation | low |

| Alcohol tolerance, % vol. | 10 |

| Sentimentation | slow |

| Optimal temperature | 10-15°С |

| Total amount of yeast, billion/g | ≥ 4,0 |

| Dosage | from 80 to 150 g/hl |

| Flocculation | high |

| Alcohol tolerance, % vol. | 10 |

| Optimal temperature | 24-33°С |

| Dosage | 3-8 g/l |

| Producer | Angel |

| Operating temperature | 24-33°С |

| Max.temperature, C | 33 |

| Optimal temperature | 24-33°С |

| Dosage | 2-4 g/l |

| Producer | Angel |

| Operating temperature | 24-33°С |

| Max.temperature, C | 33 |